The best technology

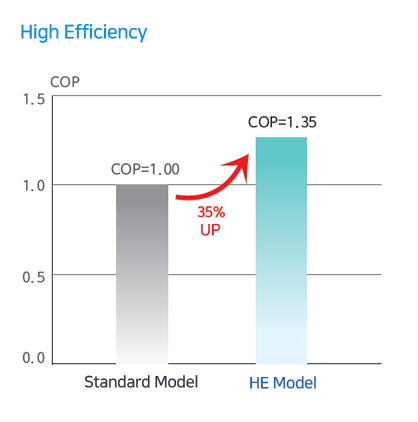

The most advanced level of technical power

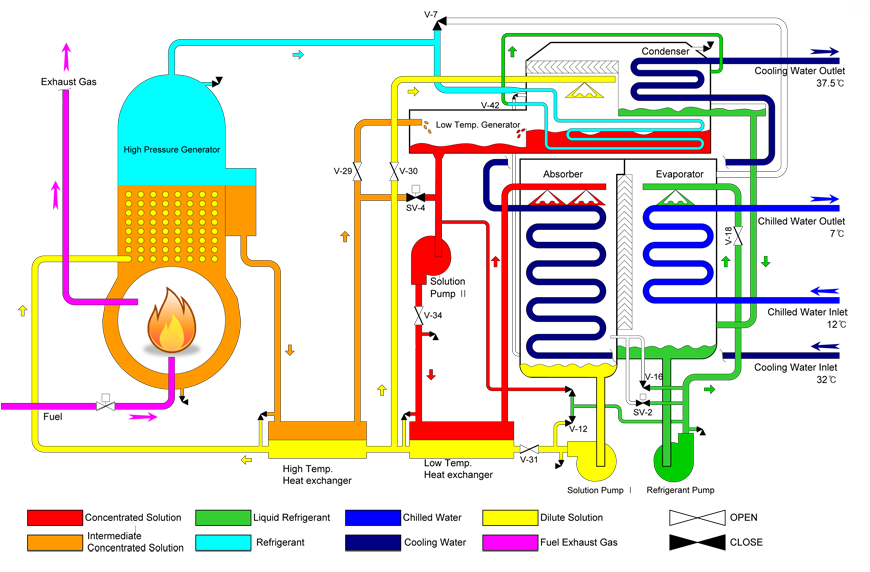

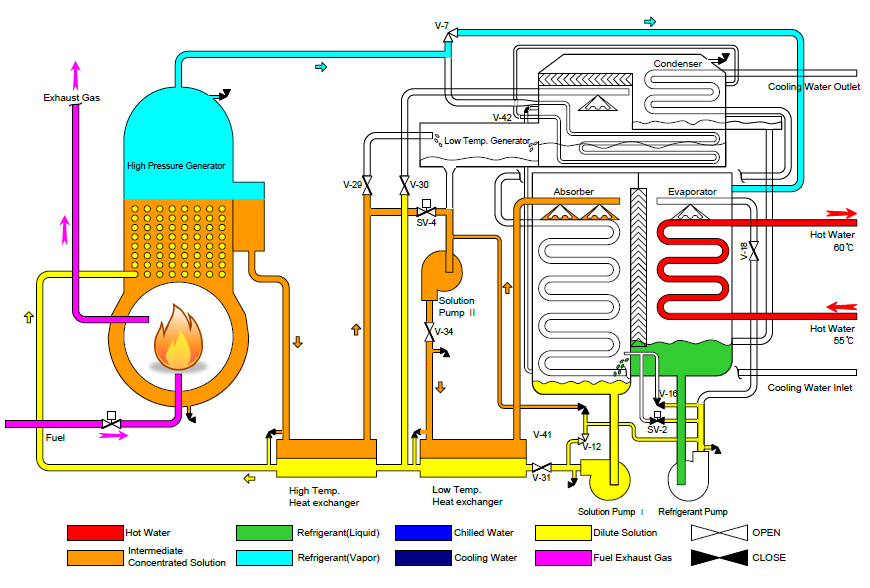

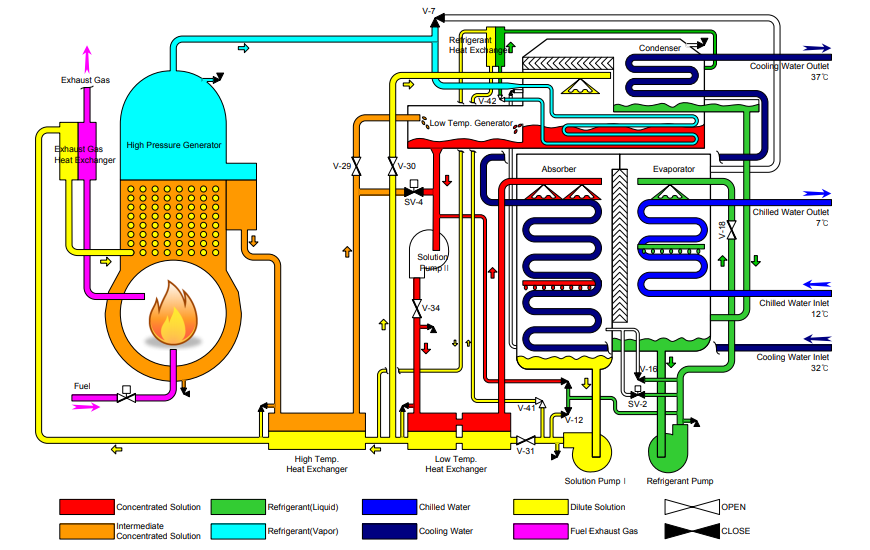

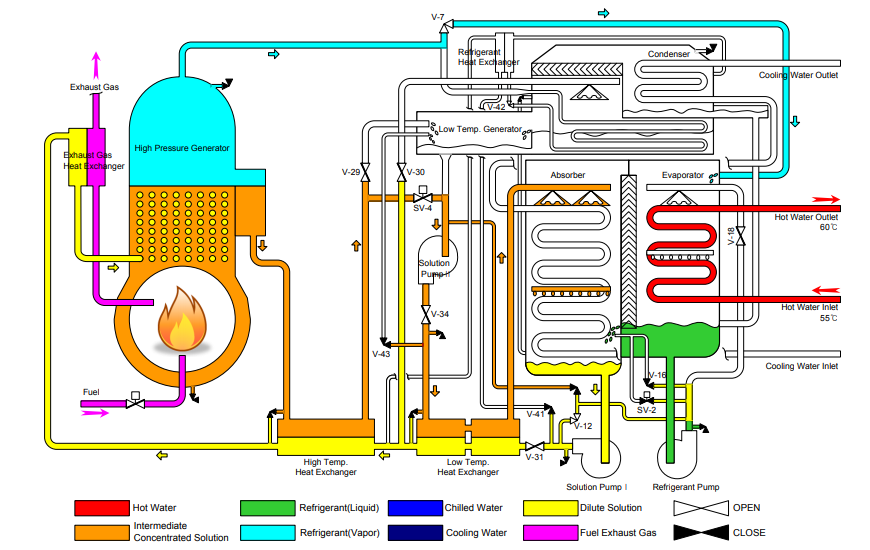

Automated operation and control

Compact, light-weight design

Faster start-up/shut-down and dilution time

Reduced steam consumption

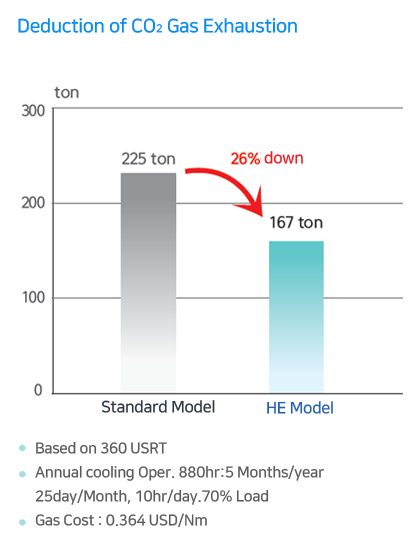

Improvement of fuel efficiency in partial load operation

High reliability

Perfect capacity control

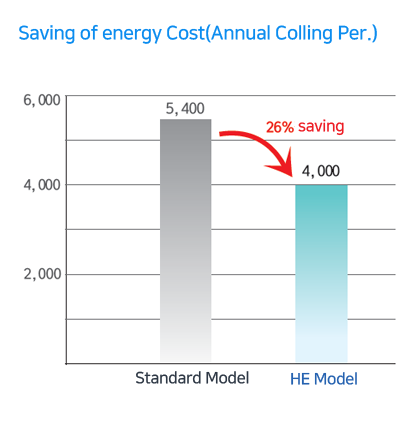

Significant saving of power cost

Employment of special spray nozzles

Intorduction of new extraction system

Automatic anti-crystallization system

Perfect safety protection system

Divisible design